‘WeAreAble’ 3D printing Kimono collection I ‘Linea Pelle’ in Milan with Stratasys – Ganit Goldstein

The new 3D printed ‘WeAreAble’ collection by Ganit Goldstein presenting a new manufacturing process, showcase the ability to use multi-color 3D printing within the world of fashion and textiles, using integrated techniques of crafts and 3D scanning. Two outfits were produced using polyjet technology directly onto the fabric, a new approach that presents the characteristics of textiles in 3D printing combining form, color, and flexibility within the study of new materiality. The inspiration for the printed Kimonos comes from the IKAT traditional weaving process, where unique patterns are becoming new gradient and harmonic surfaces in 3D technology. The combination of past and future techniques allowing tailor-made production with unique materials and parametric patterns.

These two outfits present a hybrid working process of embroidery and 3D printing technology, mixing 2D and 3D design software. ‘WeAreAble’ kimonos produced using a unique combination of colors and materials before the fabrication of the textiles, including new transparent material, presenting a crystal-like look.

“In fashion, it’s important that we continually optimize and evolve to introduce new design forms. During the past year, I experimented with numerous different fabrics and technologies to incorporate 3D printing within textiles. Achieving this milestone takes us away from 2D design and opens up a world of wearable 3D garments”.

Each garment is crafted from 3D to 2D CAD manipulations which create a precise piece of fabric for the garment, allowing the outfit to be assembled without the need for sewing. The 3D design workflow creates a single garment efficiency with 3D materiality that can produce just in this technology. This is a unique approach for the future of 3D printing in the world of textiles.

In the following video, we present Ganit’s journey through the Re-FREAM research, together with Stratasys, Haratech, Profactor, F&T department at the university of design in Linz.

The video also can be found following this link

From 22 September 2020, the kimono presented in the prestigious ‘Linea Pelle’ exhibition in Milan by Stratasys team, showing several outfits and textiles from Stratasys Art, Fashion & Design collections which brings a closer look at the new technology for printed textiles using polyjet technology. The 3D printed kimono will be presented as part of the permanent exhibition for the following months in D-house, Milan, Italy.

since launching, the project covered in many articles including 3D printing industry article , Ecotextile News and Just-style publishments. The latest publication includes an interview with Ganit

Goldstein in i24 news, covering the workflow along the time of Covid-19. The full interview can be found here.

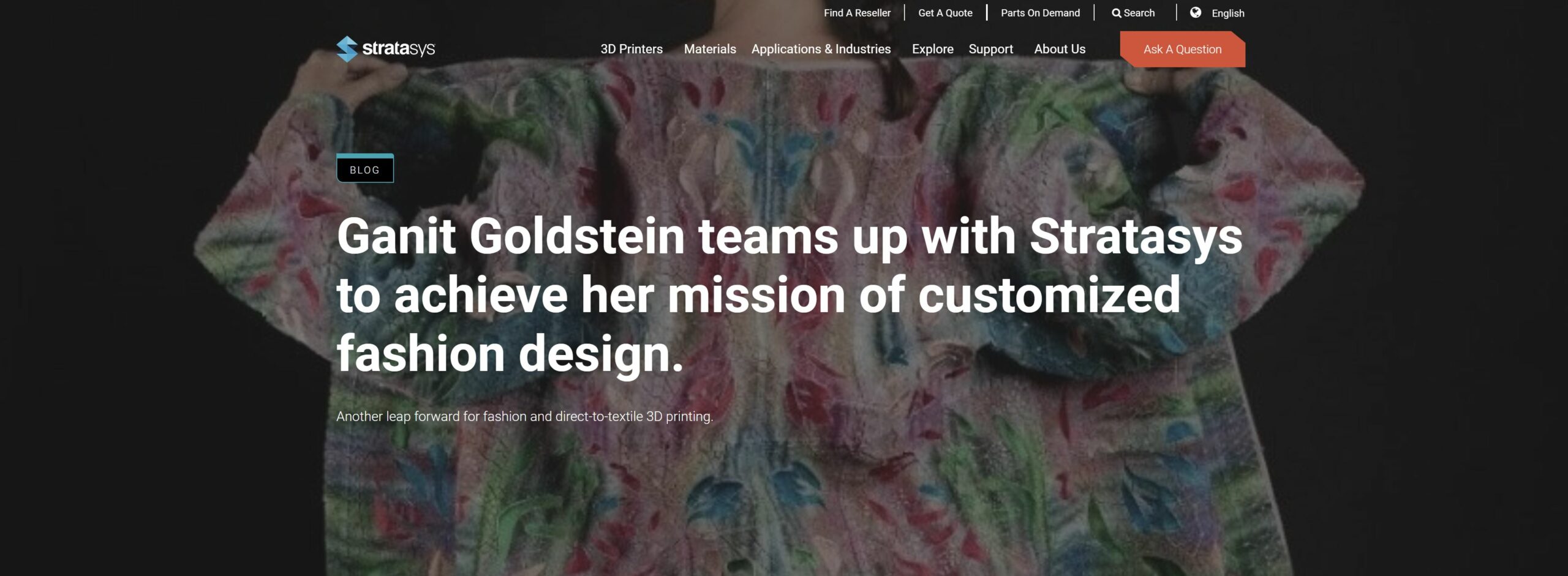

Stratasys also covered the latest developments in their blog post ‘Another leap forward for fashion and direct-to-textile 3D printing’

The 3D printed garments can be seen in a Virtual Reality app, engineered by Yoav Goldstein, a deep learning software engineer in Intel®️ RealSense™️ Group that develops applications in the fields of computer vision, autonomous driving, virtual and augmented reality. The realistic 360 exhibition space displays a collection of digital and printed garments. This allows the audience to view the 3D collection in full virtual reality space, in a new way that presents the customized garments from the body scan, from virtual to physical 3D printed outfits, bridging the gap between our new reality of social distancing. This is the reason for building the virtual exhibition with VR headset and browser setups.

The project presented in the PI Apparel Europe 2020 together with Yokai Team and Christiane Luible-baer from hub Linz, presentaing in 2 days virtual summit our 3D developments from all across Refream teams.

The project has been selected as a finalist for finalist for purmundus challenge 2020 and will be presented at the Formnext Connect from October 28th 2020. These days, the kimono presented in the Stratasys Headquarters for the Art & Fashion collection in Rechovot, Israel.

For more information about the ‘WeAreAble’ project, you can see Ganit’s previous blog posts: Hybrid traditional & futuristic techniques, 3D tools for fashion design, Reverse engineering term in the world of fashion.

you can also see the addtional 3D printed outfits made entirely using home printer in the following blog posts about Ars Electronica and sustainability approach to 3D printed garments

Thanks to the great team of Re-FREAM that supported this exciting journey, and I hope we can see more developments and new opportunities for the future of fashion in the context of 3D Textiles. Feel free to contact me for more information: ganitgoldstein1@gmail.com, Instagram @ganitgoldstein or website: www.ganitgoldstein.com.