Injection Molding

About the project

About the Technology

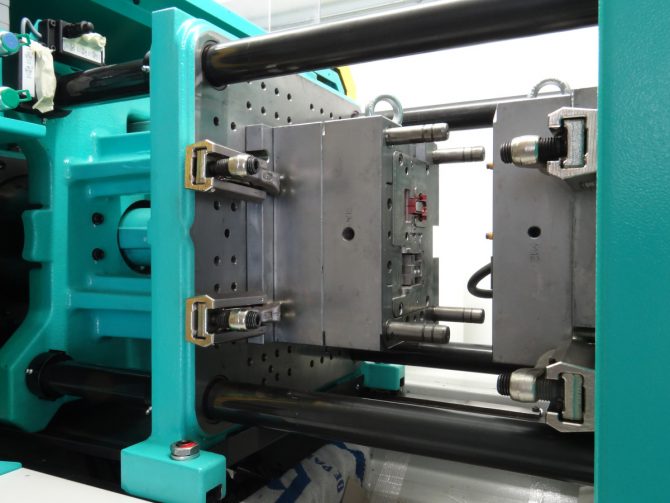

Injection molding is a molding process, where the respective material is liquefied (plasticized) and injected under pressure in an injection molding tool. In the tool, the material consolidates through cooling or a crosslinking reaction. The cavity of the tool determines the shape and the surface structure of the finished part. With this method directly usable parts can be produced inexpensively in large quantities.

The toll cost accounts for a large part of the necessary investment. Polyjet printed tools can be used for small volume production (lifetime and size limited) parts to reduce the tool costs but still have access to many strength thermoplastic materials. Due to the orientation of the macromolecules in the molded part, the strength and mechanical properties are the best achievable for a given material.

Usual Areas of Application

Any plastic processing industry (transports, medical, sports, household, tools, accessories…)

Materials used in Re-FREAM

Extremely wide range of plastic resins with variations in color, hardness, transparency, filling, electrical and thermal conductivity, chemical resistance, biocompatibility, UV resistance…

Technology is used by these Re-FREAM Partners