Vacuum Casting

About the project

About the Technology

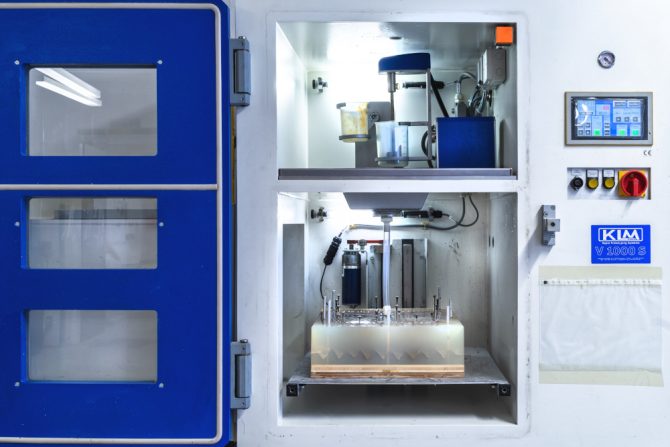

Vacuum casting is a common process for rapid and cost-effective duplication of master models. With the help of an original model or 3D printed model, a silicone mold is created, which allows the casting of several identical parts with polyurethane casting resins. The use of a vacuum chamber prevents air pockets in the mold and component. More than 50 different resins can be used. The range extends from hard plastics (reinforced / unreinforced) over transparent parts in different colors (can be colored) to elastic molded rubber parts with different textures. Limited food-graded materials are available.

Usual Areas of Application

Aviation industry, modelling, fashion objects, any small-scaled industrial production.

Materials used in Re-FREAM

Polyurethane resins in many shades color, hardness, transparency, reinforcement.

Technology is used by these Re-FREAM Partners

Haratech (Linz, Austria)

Hubs

- Hub Linz: From 2D to 3D