Needs-Based Clothing Design requires visual communication

When explaining my design approach towards bra diversity to the general public, I frequently encounter misunderstandings with conversation partners who are new to the topic of breast cancer. Especially when talking about urgently needed alternative bra options that cater to the needs of females with …

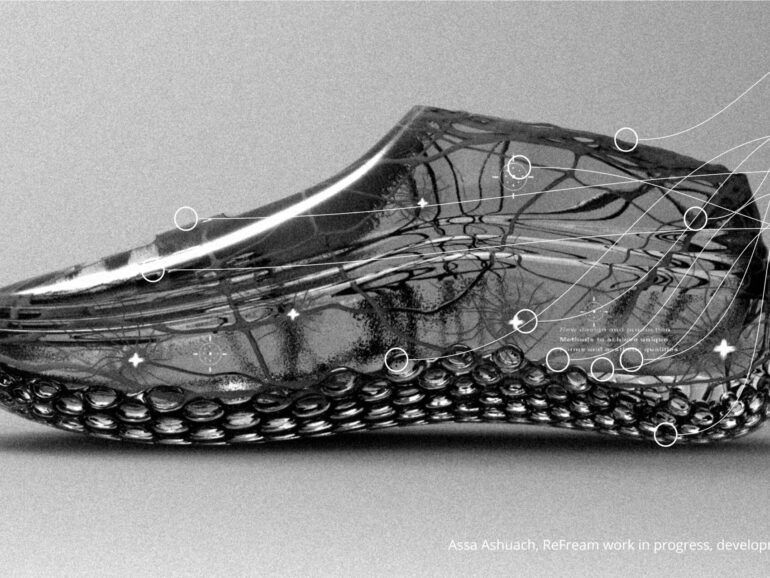

Innovations in personal fit – Assa Ashuach Refream project ‘Time Based Design’

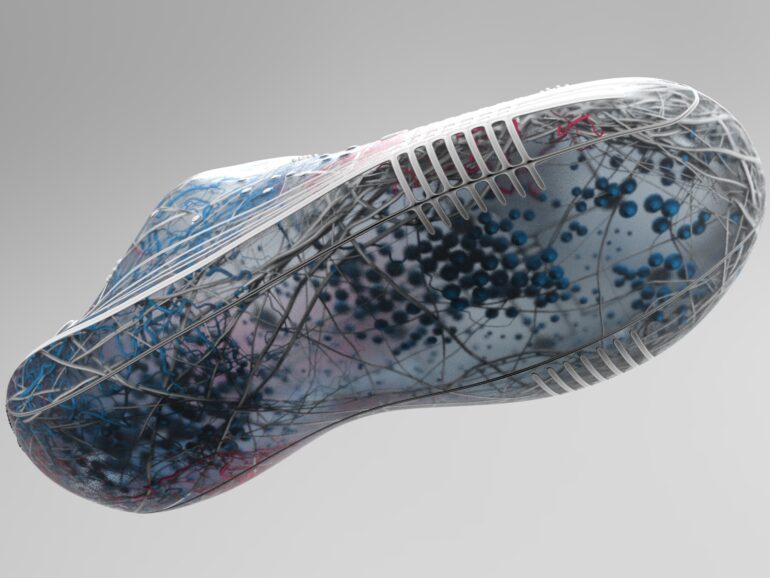

Evolve IM’ biometric evolutionary footwear and midsoles Shoes and midsoles that studies its user and improves over time. We propose a new evolutionary footwear design approach, whereby user sensors biometric data is collected over time, to achieve a gradual improvement of the shoe. Innovations in …

Evolve IM’ biometric evolutionary footwear – At Milan MICAM X tomorrow

Excited to finally present my latest ReFream EU funded research, titled ‘Footwear Time Based Design’. With many thanks to the the ReFream team and project, that was set to rethink fashion and its synergies to life and science. Invited by our dear friend Federico Brugnoli, …

Prototyping, natural dyeing and laser cutting

Prototyping, natural dyeing and laser cutting During this whole process, garment design and manufacturing has been at the center of our project. I have subcontracted professionals in this area as to have a better and more experienced approach into creating these garments. Textiles have been very …

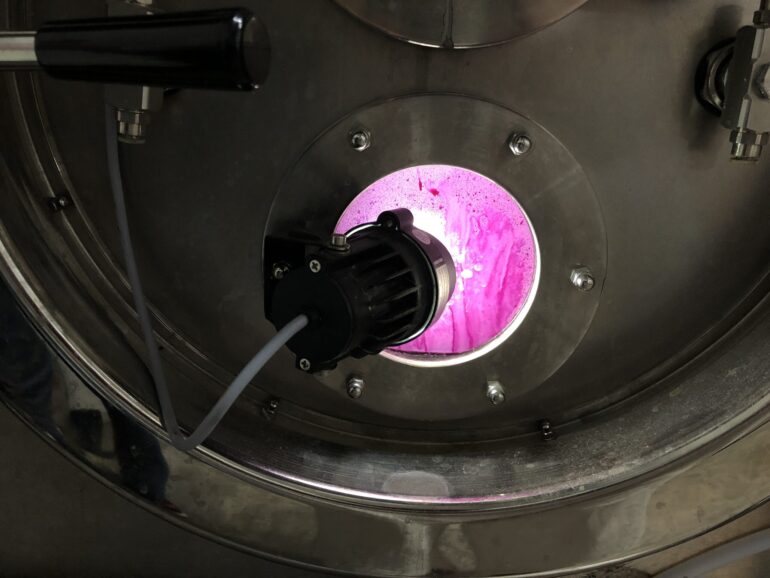

Bacteria Dyeing

Dyeing with bacteria Bacteria experimentations: During these lasts months we have been thoroughly fermenting bacteria for dyeing with my mentor Alicia Romero, from the microbiology lab at Aitex. We conducted various experiments with our 2 strains of bacteria to see how to get them to …

Needs-Based Clothing Design and textile preferences

Clothing design may not be considered a factor in the breast cancer recovery process. However, as the first layer of material that comes in contact with our skin daily, clothing plays a constant role in our perceptual experiences of touch – while dressing and undressing, …

Assa Co researching ‘Footwear Time Based Design’ with Stratasys, Haratech and Profactor

NOTE: Featured image (above) is a concept 3D illustration, and not attempting to be anything like the final design ; ) The co research was focused on the exploration of new footwear design and manufacturing methodologies, technologies, and the development of a hybrid approach to …

POSTNATURAL PROSTHESES: GRANULAR FORMATIONS AND POLYJET SAMPLES

Our Co-research phase started by experimenting with Stratasys on PolyJet 3d printing on fabric. The technology allows to augment a textile by printing three-dimensional structures onto it, whose shape, colour, transparency and flexibility can be controlled through a digital 3d model, at the resolution of …

POSTNATURAL PROSTHESES: LINEAR FORMATIONS AND POLYJET SAMPLES

Our Co-research phase started by experimenting with Stratasys on PolyJet 3d printing on fabric. The technology allows to augment a textile by printing three-dimensional structures onto it, whose shape, colour, transparency and flexibility can be controlled through a digital 3d model, at the resolution of …

Thinking Footwear through a Regenerative Polyculture

The starting point of the project Syntropia is to develop a shoe based on biomaterials which can grow on and be harvested from the same regenerative polycultural field. Regenerative agriculture is a system of farming principles and practices that increases biodiversity, enriches soils, improves watersheds, …